Titan Arm

Month

We’re honored that our project has received 1st Runner Up in the National Institutes of Health (NIH) Design by Biomedical Undergraduate Teams (DEBUT) Competition. Our team competed in the category “Technology to Aid Underserved Populations and Individuals with Disabilities”.

Niko and McGill represented the team this past week in Washington DC, where they met with The Washington Post, Boot Camp radio, and the Wall Street Journal.

We’re happy to report that Team Titan was awarded first place at the Cornell Cup 2013! Thank you to Cornell and Intel for organizing a remarkable competition.

Our project has been featured on the Discovery Channel “Daily Planet” segment. Check out the video here – our part comes in around the 4 minute marker.

Off we go! See you soon Orlando!

We’re honored to be featured on both Engadget and Gizmodo tech blogs. Check it out!

Our team is headed down to Disney tomorrow to compete in the Cornell Cup! We’ll be making some last minute tweaks tonight and then catching an early flight – wish us luck!

Our team is happy to report that we took 2nd place overall in Penn Engineering this past Thursday at the All Engineering Senior Design Presentations. Thanks for all the support! Our new teaser video is below, and we should be receiving a link to our full presentation on YouTube soon!

Today, Team Titan presented our project at the Mechanical Engineering Senior Design Day. Attached to this post, you’ll find our poster with information, as well as our “teaser” video below.

We’re happy to report that our team was honored with the Judge’s Award for overall project excellence. We’ll be one of three teams representing that Mechanical Engineering Department at the All Engineering Senior Design presentations next week.

Hey there!

The team has been hard at work completing our exoskeleton. We’ll be demonstrating our exoskeleton at the MEAM Senior Design Poster Session this Wednesday from 9am-4pm.

Here’s a teaser picture to get you interested!

After much machining, the suit has been put together!

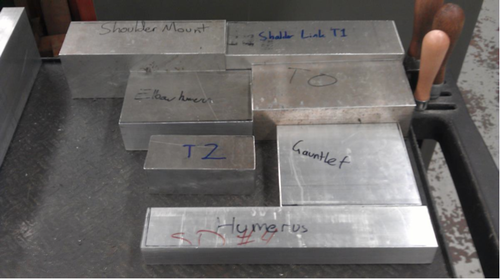

After many long, 14 hour-or-so days in the machine shop, the majority of our components have been manufactured.

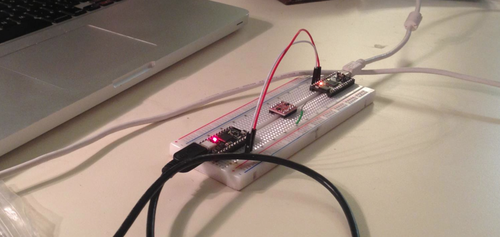

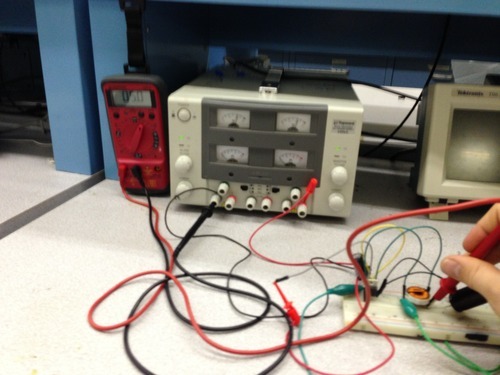

The break was spent developing serial communication code between the M2 and BeagleBone in Python and C. In addition, the power regulation circuit was implemented on breadboard and proved the DC-DC Buck Converter worked as intended – the voltage was very close to the target voltage of 5V.

The team has embarked on a spring break challenge: machining a large number of components for the exoskeleton and advancing the transmission and electronics subsystems.

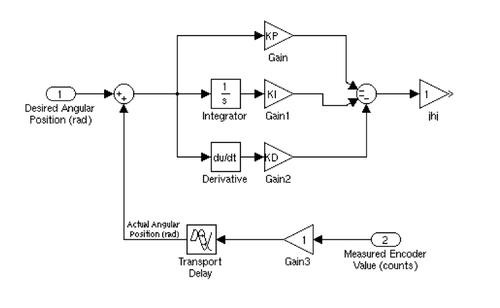

As we learned in our controls class at Penn, Matlab’s Simulink package provides a powerful way to build and test control systems. As such, our team has started building a Simulink model for use in simulating suit behavior and response.

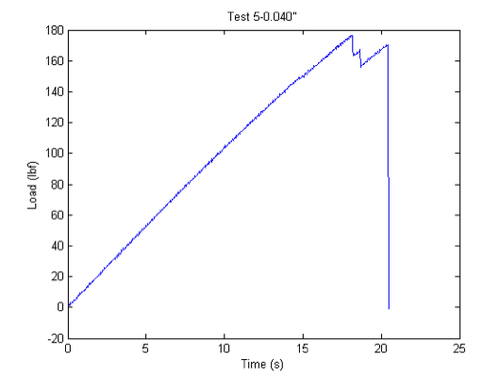

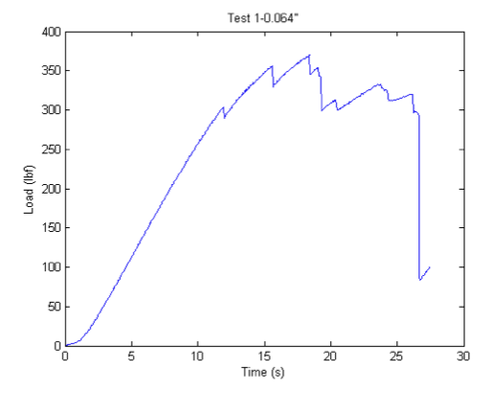

Based on the last testing, our team developed grips that were more accurate to the forces that the cables would be experiencing. Two set screws were used to grip down on the cable – two of these blocks were used to hold the cable in between the grips of the machine.

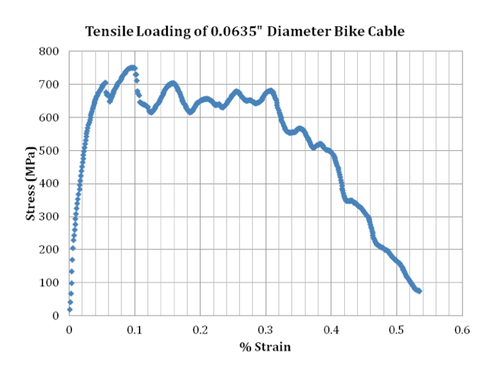

The given testing gave more reasonable results, though slipping of the cable is clear in the stress vs. strain curve below.

The team performed analysis on two types of bike brake cables in order to determine their stress strain curves using an MTS materials testing machine. We’ll be continuing testing with the 0.064" diameter, as it withstood almost 300 lbf, and we’ll be expecting loads of 180 lbf in the suit.

These tests were conducted by simply gripping the bike cables in the MTS machine. However, the given yield strengths are less than predicted – by gripping on the actual cable, there is increased stress at these points. Further testing will be done with a gripping style setup, possibly by using set screw attachments.

We’d like to thank our newest sponsor, Monster Energy! They’ve supplied the team with a hefty amount of energy drinks to sustain our long nights in the lab.

See our other contributors on the sponsors page.

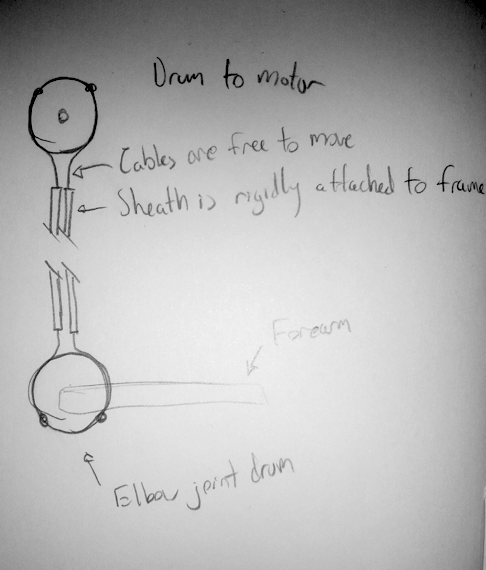

This week, the team met with Jonathan Fiene to talk about forms of actuation and issues implementing a cable drive system. In particular, we were trying to solve the problem of varying rates of bicep and tricep extension. A novel solution our team developed was to use a 1:1 spool system – one mounted on the motor, and one of the elbow joint. This solves our rate-variation problem, though the exact sizes of the spools must be solved out based on the motor selection. Check out the image below.

The motor selection was narrowed to Maxon’s line of DCX motors with a custom combination of motor, gearbox, and encoder. Consultation with a Maxon representative will be crucial in finalizing the motor order.

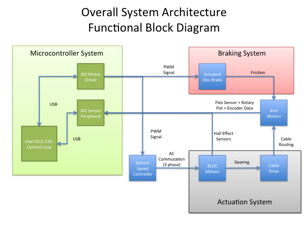

Our team developed an initial functional block diagram to separate the different systems of the Titan Arm. We’ve divided into microcontroller, braking, and actuation.

We’re pleased to announce that we’ve been accepted to the Cornell Cup Competition! Cornell and Intel have teamed up to present an embedded systems competition. We’ll be competing this May is Disney World, Florida! Stay tuned.

Based on our actuation selection, a cable drive will be implemented on the exoskeleton to transmit the power from the motor to the elbow joint. A cable drive system allows for non-localized actuation. Other exoskeletons, such as HAL (image below), use localized motors for actuation. With non-localized actuation, it is possible to increase the motor strength and decrease the weight at the joint extremities.

We’ll be investigating cables and sheathing to transmit the force from the back to the elbow joint.

After months of deliberation, our team decided to purse an actuated upper body exoskeleton for use in the fields of healthcare, search and rescue, and strength intensive occupations.

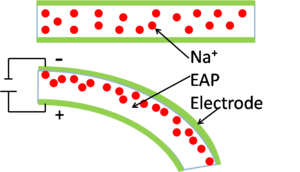

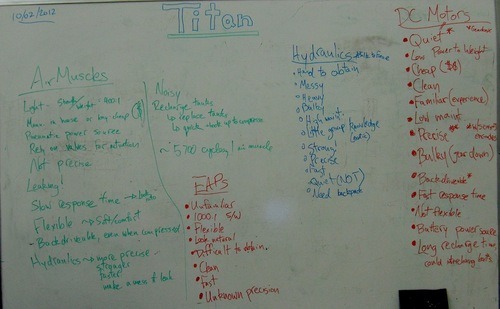

Isolating simply the actuation subsystem, our team researched four different forms of actuation:

Fig. 1: Our whiteboard brainstorming session.

Our team has decided to move forward with a DC motor actuation system. This system was chosen because the team has experience; DC motors are already relatively inexpensive, clean, quiet, and precise.

One way of creating a natural user experience is to give a quick, smooth response to the user input. This is no small feat; how can you tell when a user requires additional strength? Electromyography is a potential solution. Electromyography, or EMG, is a way of sensing muscle activity through electrical signals. When muscles are activated by the brain, an electrical potential can be measured in the range of 50uV to 30 mV. By amplifying and filtering the signals, it’s possible to read and decompose the signals. When the muscles are inactive, the electrical potential is low; however, when lifting an object, the electrical potential rises. As the work required of the human increases, more muscle is called on to help lift the object, increasing the potential even higher. Therefore, using the correct sensors and filtering, it’s possible to scale the amount of aid from an exoskeletal suit.

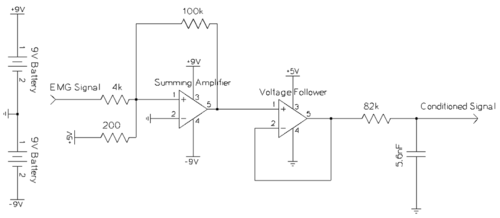

Figure 1: The circuit used for amplifying and filtering EMG sensor data.

One of the team members’ brothers, Steve McGill, worked on a project with EMG sensors a few years back for his senior design. We enlisted his help in developing a EMG solution and borrowed his circuit, still working after three years of inactivity (Fig. 1). The sensors he lent us were high quality collocated EMG pads (see Fig. 2). This setup was found to be a “binary” approach, capable of determining if there was any muscle activity or none at all. This result was exciting, especially so early on in our project, but not ideal. An ideal signal would clearly represent a gradient of muscle activity, delineating both small and large loads. Luckily, a little digging online led to some interesting circuits that we’ll be investigating soon!

Figure 2: Two EMG sensors. These were applied directly to the skin and attached with typical bandage wrap.

The transition from no assistance to assistance could be triggered with these EMG sensors, but it’s not clear yet how to stop the external support. For example, when lifting a heavy box, the assistance could be triggered once the EMG signal crosses a certain threshold. This would allow the user to lift the box in a continuous angular rotation. However, a trigger must be set at the desired arm angle to lock the user’s arm in place. Current systems use an external controller to actuate and stop the user’s motion; it would be ideal to encapsulate the system and localize control to the user.

In order to get a better grasp of the applications of our project in physical therapy, our team met with Jennifer Dekerlegand, a physical therapist at the Hospital of the University of Pennsylvania (HUP). Jennifer has worked with engineers at Penn before and has a thorough understanding of the world of physical therapy. The biggest takeaway from our meeting was that developing the strength of the patient is much more important than developing the range of motion. To that end, we’ve put an emphasis on strength development in our design plans.

Jennifer will be a knowledgeable resource as we continue to develop and refine our project scope. Already, she’s helped us rule out the use case of a nursing assistance exoskeleton – such a device would be work than it’s worth. She’s also given us personal stories interacting with the Ekso Bionics lower body exoskeleton and the positive impacts on the patients.

Our team is designing an untethered, powered, upper body exoskeleton for use in the fields of rehabilitation and therapeutic application, as well as occupations requiring augmented strength. Though systems exist, past exoskeleton endeavors have led to bulky, expensive, invasive, and tethered solutions. The challenge is to build an exoskeletal system that is inexpensive, streamlined, and wireless.

Our solution is unique in that it will be a low-cost, ergonomic device actuated through sensors measuring the user’s motion and muscle activity. Through onboard sensing, the skeleton can provide rich data, such as range of motion or strength for use in physical therapy. This data can be used by doctors and patients to more accurately track improvement over time. With its low cost, hospitals could employ multiple devices and aid a larger audience of patients; the devices could even be used at home for physical therapy, which would dramatically increase quality of life for patients.

Outside of physical therapy, augmented strength is applicable to physically intensive occupations, as well as search and rescue operations. Each year, thousands of workers must take leave due to injuries triggered by heavy lifting; with augmented strength, workers could avoid harmful situations.