More Cable Testing

Based on the last testing, our team developed grips that were more accurate to the forces that the cables would be experiencing. Two set screws were used to grip down on the cable – two of these blocks were used to hold the cable in between the grips of the machine.

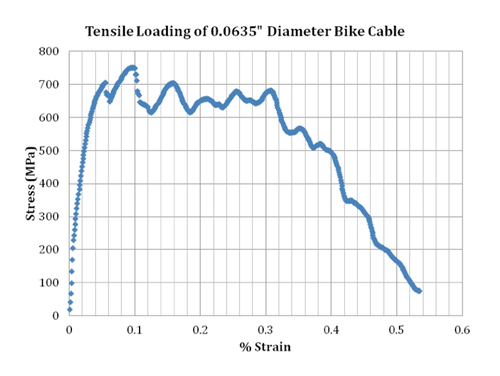

The given testing gave more reasonable results, though slipping of the cable is clear in the stress vs. strain curve below.